Applications to Steels

Calculate the following based on your actual alloy chemistry:

Application Examples

Critical Temperatures and Phase Fractions in P91 Steels

P91 steels rely on a quench and temper microstructure to obtain good creep strength and toughness. If the A1 temperature is exceeded during tempering, then untempered martensite will remain after heat treatment, leading to poor toughness. Phase transformation temperatures can vary with chemistry and this can be calculated using Thermo-Calc.

This figure shows the equilibrium phases as a function of temperature for a nominal composition of P91, with A1, A3, liquidus, and solidus listed on the diagram.

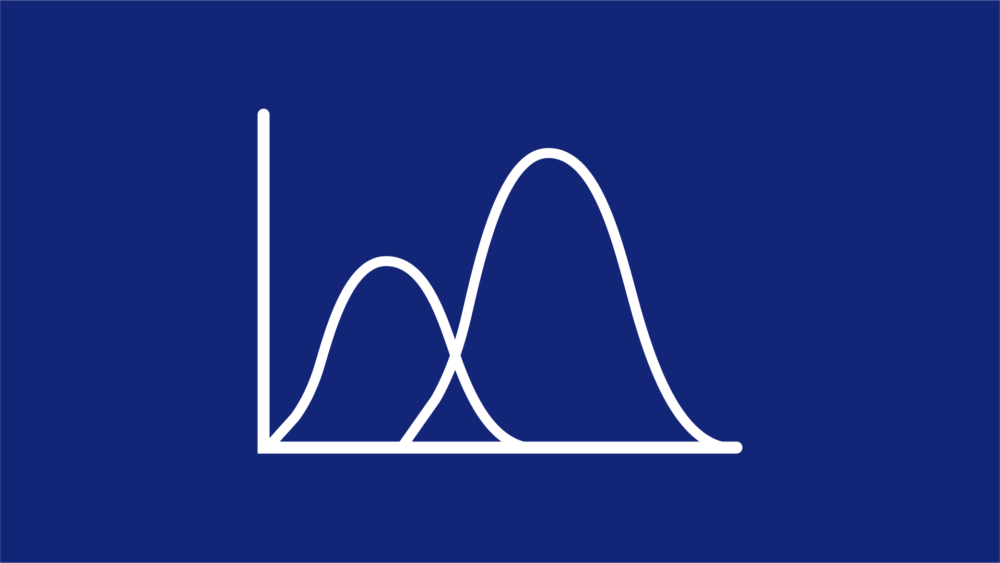

A1 Temperature Distribution for P91 Base Metal and Weld Filler Metals

In the above example, the A1 temperature was calculated based on a nominal composition of P91. This temperature can vary with composition and can be different between the weld metal and base metal, but this is hard to capture for every possible heat of material without performing many experiments. With Thermo-Calc, you can calculate this across the entire composition space.

The histogram here shows the A1 temperature calculated for 200 compositions each that fall within the P91 base metal and two weld filler metal matching composition specifications. As can be seen, if the post weld heat treat temperature is selected according to the base metal compositions, the A1 temperature could be exceeded in the weld metal resulting in fresh martensite formation.

T-Zero Temperature Determination

Several steel alloys undergo a diffusionless phase transformation, such as martensite transformation, that creates a hard and brittle martensite phase. The upper limit when this phase transformation can take place can be calculated using the T-Zero (T0) General Property Model included in Thermo-Calc, which calculates the so-called T0 temperature line. This is defined as the temperature where two phases of identical chemical composition have the same molar Gibbs free energy.

The plot shows the Fe-Ni binary system wherein the T0 line for the FCC_A1 and BCC_A2 phases is located in the middle of the two-phase region (dotted yellow line). No solution for the T0 temperature exists above about 30 mass% Ni. This example can be found as example PM_G_09 in example files provided with the software.

Martensite Content for 4130 Low Alloy Steel

Many low alloy steels, such as 4130, rely on a quench and temper microstructure to obtain desired mechanical properties. The martensite transformation start (Ms) and finish (Mf) temperatures can vary as a function of chemical composition. The Ms temperature can be easy to measure, but it is difficult to determine the martensite fractions as a function of temperature. This is important to determine if any retained austenite may be present. With Thermo-Calc, the martensite fraction can be calculated as a function of temperature for different compositions.

The diagram here shows the martensite fractions as a function of temperature for a 4130 steel with nominal chemistry and agrees well with the literature value of 380 °C (ASM Handbook Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys, ASM Handbook Committee).

Determination of Spinodal Decomposition

Many steels, particularly Cr-containing ferritic steels, show a spinodal decomposition at elevated temperatures (300-600 ℃), causing an undesirable embrittlement effect. This spinodal decomposition refers to a phase separation from an initially homogenous material at elevated temperatures (Barker et al., 2018). The Spinodal Property Model included in Thermo-Calc calculates the spinodal line, which is defined by the condition where the second derivative of Gibbs free energy is zero (d2G/dx2 = 0). The locus of these points is known as the spinodal curve.

The plot shown here is a binary Fe-Cr spinodal curve for BCC that goes through the one-phase region for Sigma phase. This example can be found as example PM_G_08 in example files provided with the software.

Products Related to Steel and Iron-based Alloys

Learn more about Applications to Steels

Calphad-assisted design of high strength – ductility martensitic stainless-steels with reverted austenite

Thermo-Calc Modelling of as-cast Features and Its Influence on Final Mechanical Properties

Read several in-depth examples showing how Thermo-Calc can be used to improve steels and steel processing

The importance of steel chemistry and thermal history on the sensitization behavior in austenitic stainless steels: Experimental and modeling assessment

Challenges and opportunities in thermodynamic and kinetic modeling microalloyed HSLA steels using computational thermodynamics

Retention of Delta Ferrite in the Heat-Affected Zone of Grade 91 Steel Dissimilar Metal Welds

Continuous Casting of High Carbon Steel: How Does Hard Cooling Influence Solidification, Micro – and Macro Segregation?