About the Diffusion Module (DICTRA)

The Diffusion Module (DICTRA) is an Add-on Module to Thermo-Calc that makes modeling multicomponent diffusion-controlled transformations simple and accessible. The Diffusion Module (DICTRA) is based on the numerical solution of the multicomponent diffusion equations and the CALPHAD approach.

Questions Diffusion Simulations Can Help You Answer

The Diffusion Module (DICTRA) is a general tool for making diffusion simulations, but some typical questions it can help you answer are:

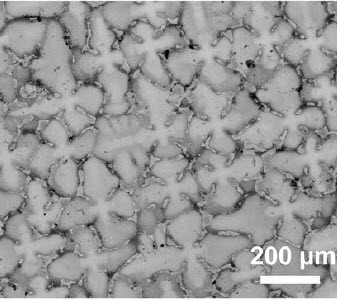

A screenshot of the Diffusion Module (DICTRA) showing the results of a moving phase boundary calculation for a Fe-C system.

The Diffusion Module (DICTRA) Allows You to Simulate:

Generic Models for Flexible Use

Databases for Diffusion Simulations

Upcoming Courses

Diffusion Module (DICTRA) Training

The Diffusion Module (DICTRA) Training is designed for beginners as well as current DICTRA users. This hands-on course focuses on using the graphical mode of DICTRA to solve engineering problems related to diffusion in multicomponent systems and diffusional phase transformations. Participants will explore multicomponent diffusion theory, mobility databases, and practical applications through interactive exercises and Q&A sessions.

We schedule courses two to three times per year, check out the course pages to see if we currently have courses scheduled.

Learn More about the Diffusion Module (DICTRA)

Thermodynamic and Kinetic Simulations on Joining and Additive Manufacturing Processes for an ICME Framework

Thermo-Calc Modelling of as-cast Features and Its Influence on Final Mechanical Properties

A comprehensive tutorial that teaches about the role of diffusion in materials and how the Diffusion Module (DICTRA) can be applied to materials design and processing.

A collection of videos demonstrating the capabilities of the Diffusion Module (DICTRA).

An experimental and theoretical study of duplex fcc+hcp cobalt based entropic alloys

Continuous Casting of High Carbon Steel: How Does Hard Cooling Influence Solidification, Micro – and Macro Segregation?

Retention of Delta Ferrite in the Heat-Affected Zone of Grade 91 Steel Dissimilar Metal Welds

Application of finite element, phase-field, and CALPHAD-based methods to additive manufacturing of Ni-based superalloys

A collection of references regarding the development of the Diffusion Module (DICTRA), kinetic models implemented in the software, some specific applications utilizing it, and more.