Application Example

Microsegregation During Solidification

This example shows only a few of the capabilities of Thermo-Calc together with the Add-on Diffusion Module (DICTRA) to investigate and predict microsegregation (solute redistribution) during solidification.

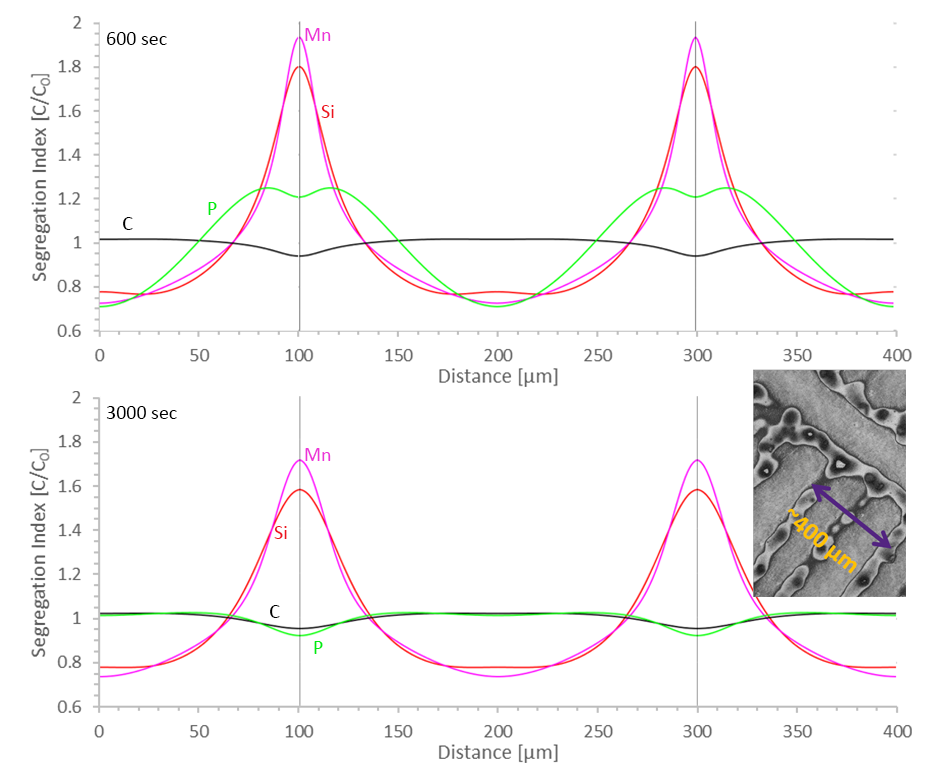

It is based on a real case where the elemental distribution of a continuously cast steel was measured revealing the concentration of the elements Si, Mn, and P as sketched in Figure 1. The profile results from the well-known segregation across secondary dendrite arms. The interesting point is that the elements Si and Mn show the expected positive segregation (higher concentrations) in the interdendritic regions. The peak of the P content, on the other hand, is shifted compared to Si and Mn, and, in fact, shows negative segregation in the interdendritic region. This is unexpected and counterintuitive.

Calculated segregation of all elements just after final solidification (600 sec, top) and after cooling to 900 °C (3000 sec, bottom): just after final solidification there is positive P segregation in the final solidification pools between the dendrite arms. On further cooling, P redistribution is controlled by slow Mn and Si diffusion resulting in the unexpected, but experimentally observed, peak shift and negative P segregation.

The calculations are based on ones performed in the frame of a research project funded by the European Union called VESPISM – Virtual Experiments to Solve Problems in Metallurgy – conducted from 2001 to 2004 (https://cordis.europa.eu/project/rcn/55407_en.html).