Thermo-Calc 2025a Available Now

New Licensing System

Thermo-Calc Software is excited to announce that we are migrating to a new License Entitlement System. The new system uses login credentials, which greatly simplifies the licensing process and brings many advantages to our customers.

Benefits include:

Redesigned Online Help

The online help receives a new look and feel in the 2025a release as well as a reorganization of the content for easier navigation.

Improvements include:

Two new examples are available demonstrating these new features, one in Thermo-Calc and one in TC-Python:

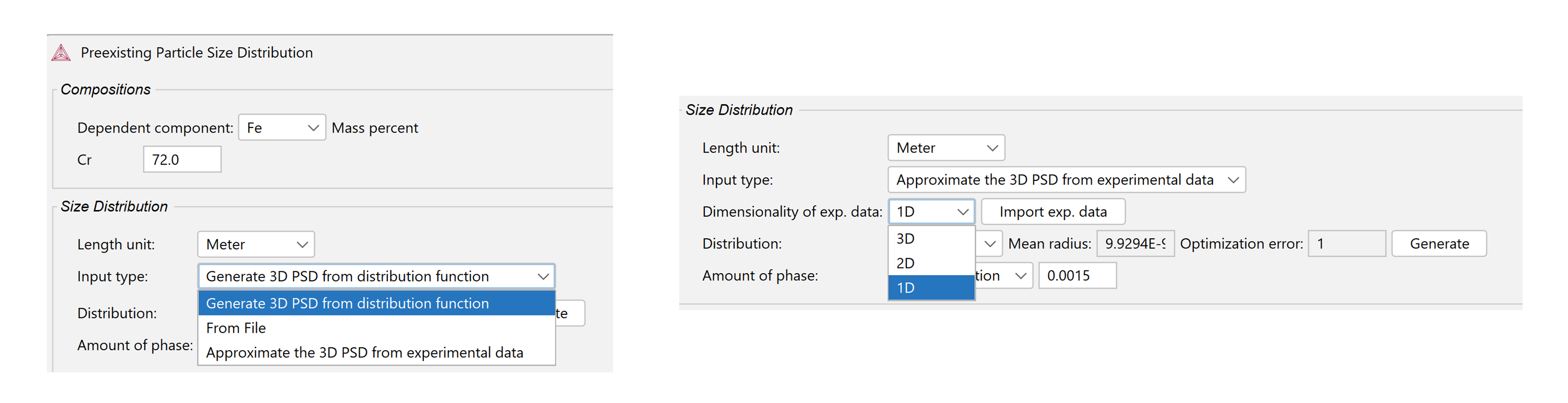

Improved Modelling of AM in the Precipitation Module (TC-PRISMA)

Work has also been done to better simulate additive manufacturing in the Precipitation Module (TC-PRISMA) and to speed up these types of simulations.

Since the release of the AM Module, users have been able to send probe temperature data from the AM Module to the Precipitation Module (TC-PRISMA) in order to model microstructure. However, these types of simulations often took a long time or failed to complete.

Work has been done to address these issues and has resulted in two new checkboxes in the Precipitation Module (TC-PRISMA) for non-isothermal simulations:

These checkboxes pre-process the required thermodynamic and kinetic data coming from the AM Module in order to save time during the precipitation simulations and ensure the calculations complete successfully.

One new example is available demonstrating these new simulation options:

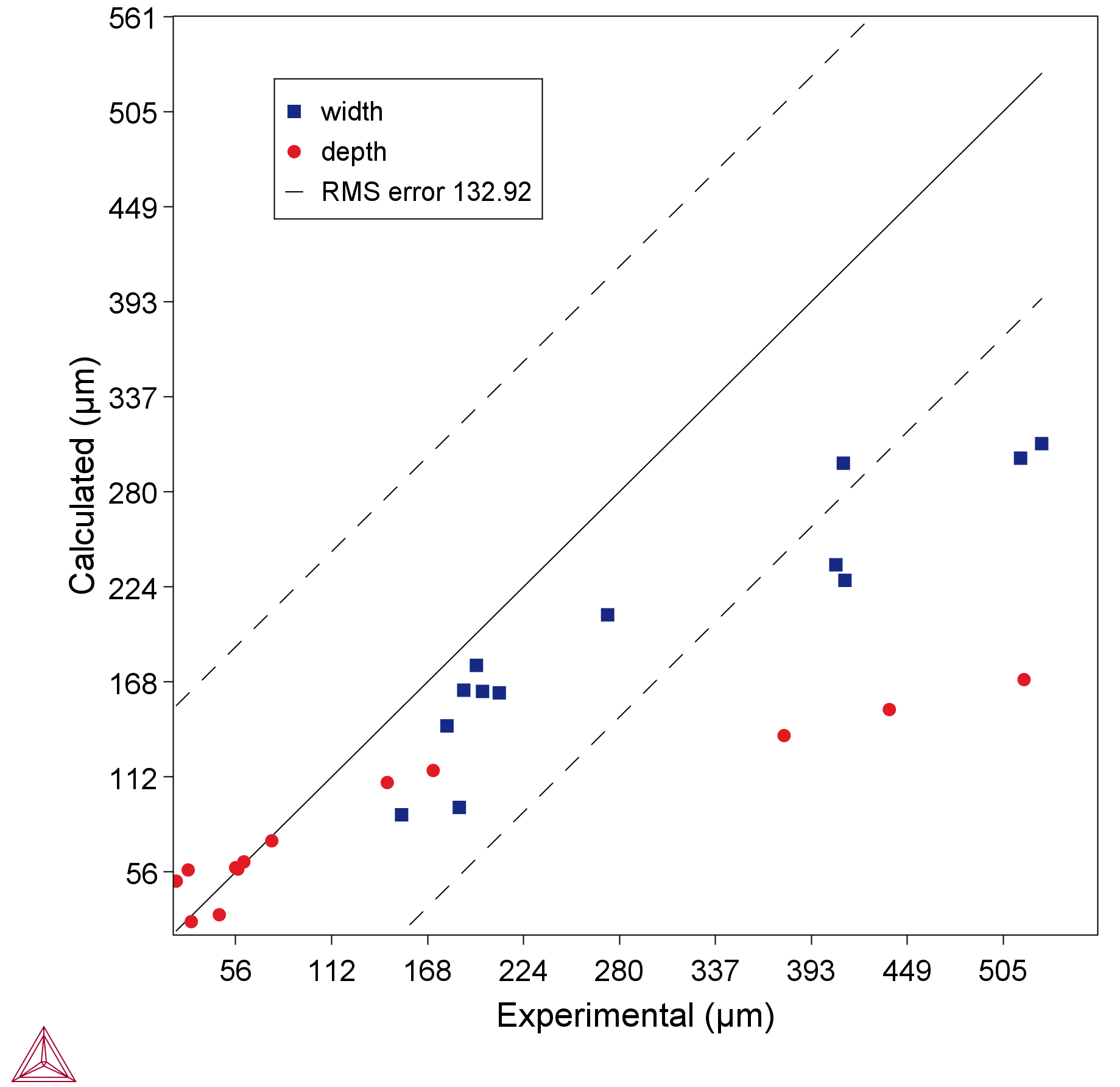

Improved Stability and Predictability for Al-alloys

Simulations for aluminum alloys have been improved in the Additive Manufacturing Module. Aluminum alloys have several challenges that make accurate simulations especially challenging, particularly in the three areas listed:

Due to these challenges, AM simulations for aluminum alloys often failed or provided inaccurate results in previous versions of the software. Therefore, work has been done to address these issues and make Al simulations more stable and accurate, namely three additions in the software. First, the absorptivity modeling that was discussed in the previous section.

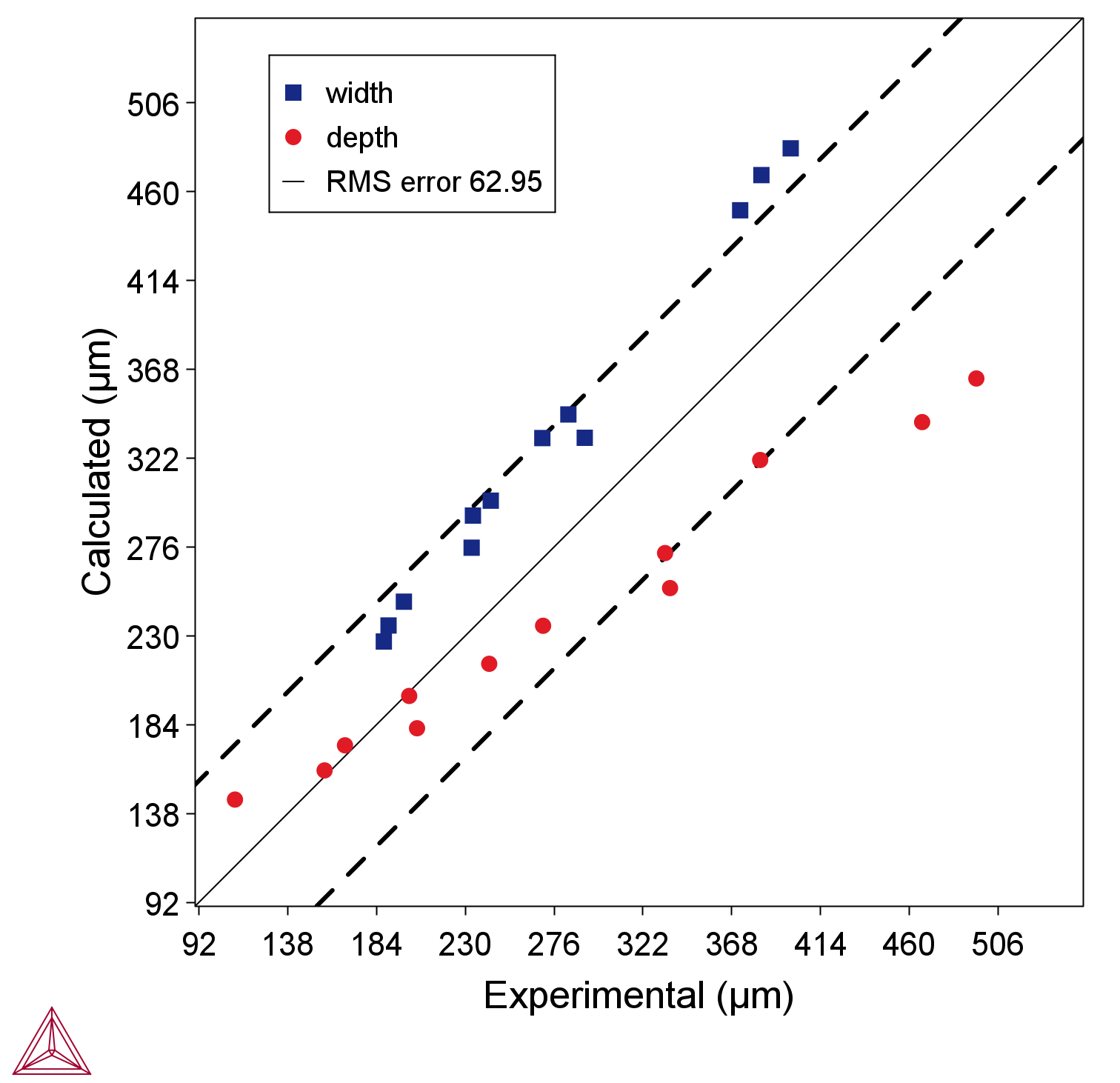

Left: Al10SiMg – abs. 20% simulated in 2024b showing disagreement between experimental and simulated results; right: from Example AM_11_Batch_Al10SiMg in 2025a showing good agreement after the improvements.

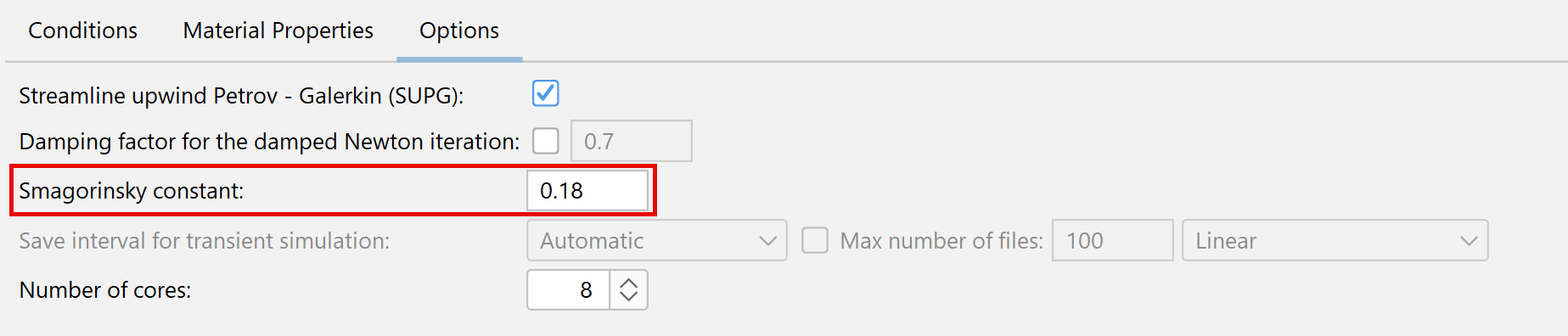

Second, in the AM Calculator, the Smagorinsky constant can now be set by the user, whereas it was hardcoded before. This allows the simulation to better account for turbulent flows.

Smagorinsky constant setting added to the AM Calculator Options tab. This is used with the fluid flow model.

And finally, a new setting has been added to the Scheil calculator that allows for interface scattering to be applied after Scheil. This improves the predictability of as-cast and as-printed conductivity for all alloys with large amounts of secondary phases, not just aluminum alloys.

This new setting has been added to the main Scheil calculator as well, not just the one related to the AM Module.

A new example is available demonstrating these improvements:

New Functionality Added to the Plot Renderer

Several improvements have been made to the plot renderer in the Additive Manufacturing Module to make it easier to work with and expand the functionality.

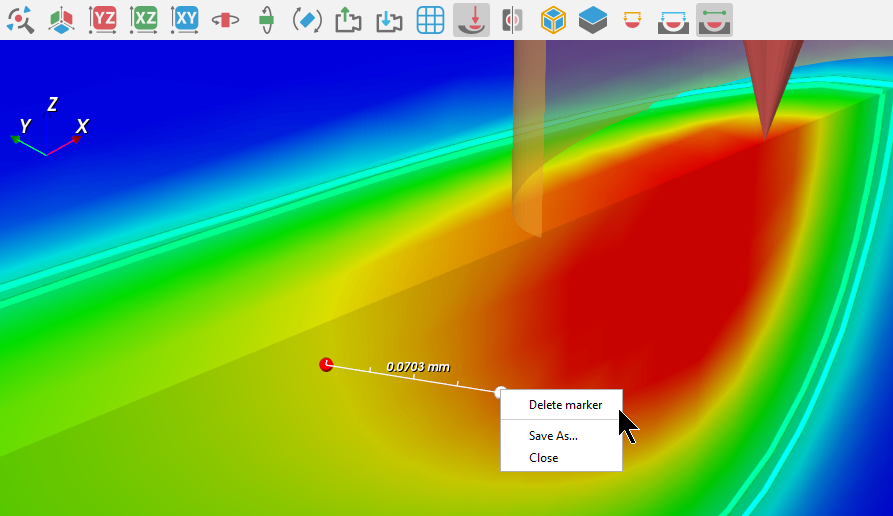

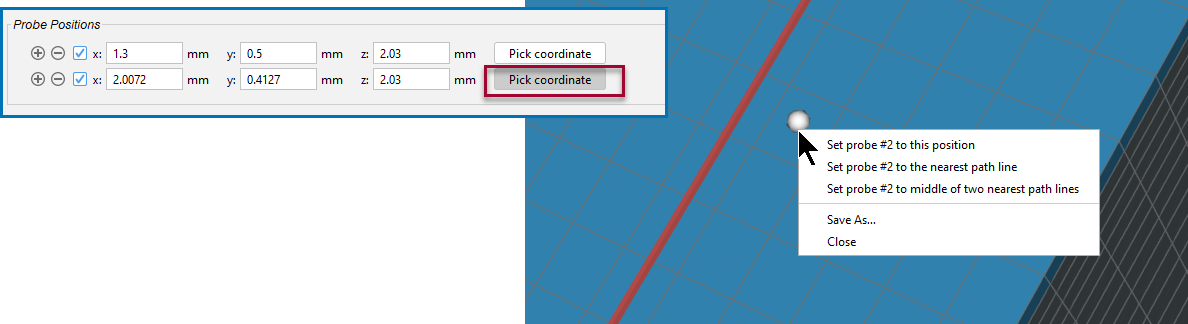

When working in the AM Calculator there are now new options available to work with various tasks. You can save an image of the geometry or a 3D plot, set probe positions, or delete markers. These options are available either as tooltips or from menus when you right-click in the Visualizations window.

New Noble Metal Alloys Model Library

A new Property Model Library for Noble Metal Alloys is available as of this release. The library includes one model that was designed for predicting the optical properties and apparent color of noble metal alloys as a function of incident light. The model is intended to assist users in achieving an attractive color when developing noble metal alloys for the purpose of cosmetic applications.

Color prediction for Ag-Au-Cu alloy using the new Optical Properties Model in the Noble Metal Alloys Model Library.

One example is available, which demonstrates three use cases for simulating color in the silver-gold-copper (Ag-Au-Cu) alloy system:

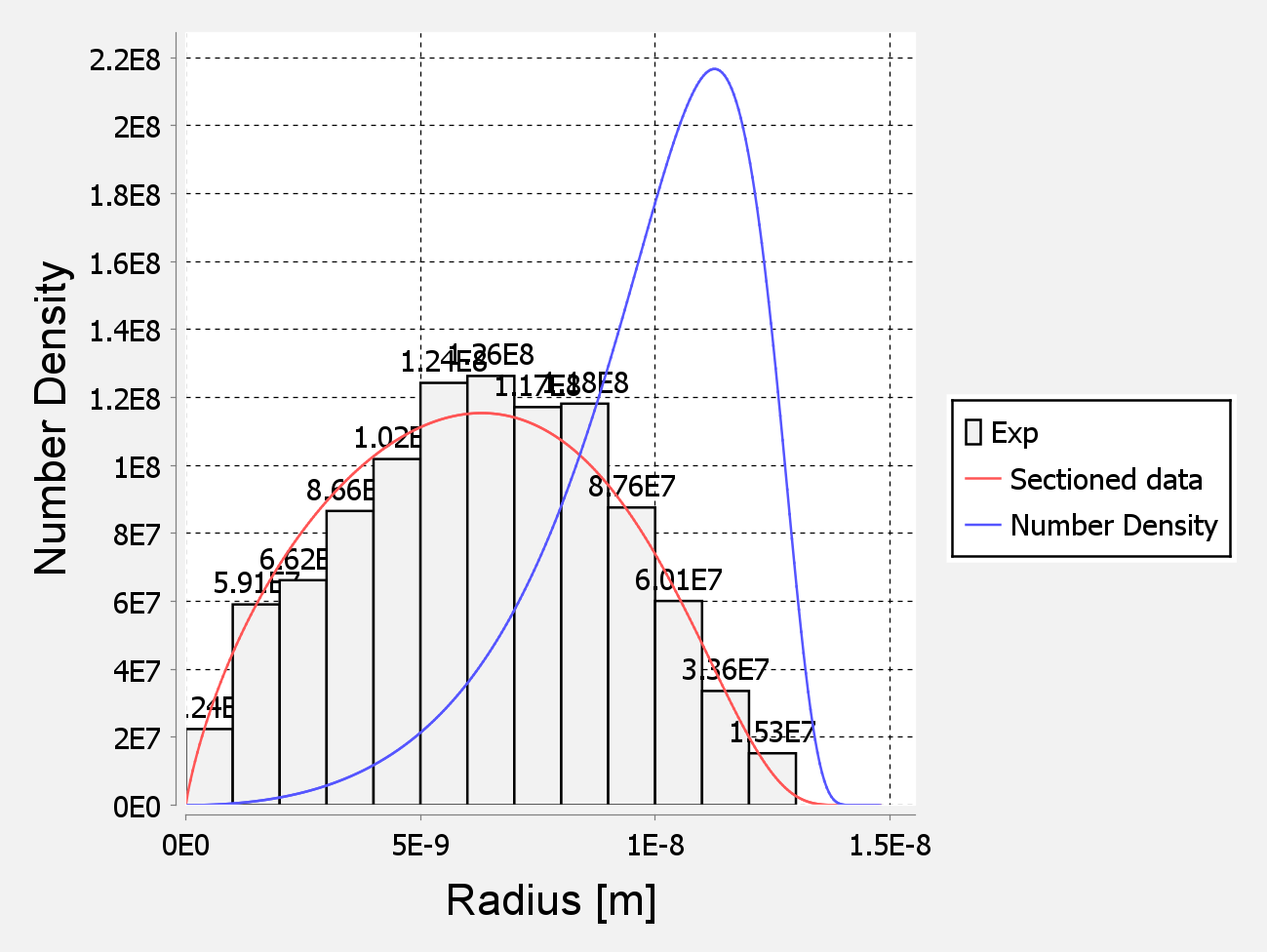

New Method for Splitting Multi-modal Distributions

A new method is implemented in the Precipitation Module (TC-PRISMA) to split precipitate size distributions in order to identify statistics of individual populations.

You can both section and split several post processing quantities.

Results from running Example P_06 in 2024b (left plot) and 2025a (right plot). The results showcase how the particle population detection has been improved in Thermo-Calc 2025a.

Example P_06 is updated to demonstrate this improvement, which simplifies the process and makes it more robust to identify individual populations:

TC-Python also updates one example and adds one example showing this:

Databases and Properties

New Databases

Updated Databases

Thermo-Calc 2025a also includes four updated databases. Read the Release Notes for more details.