Thermo-Calc 2020b is Released

Highlights of the 2020b Release

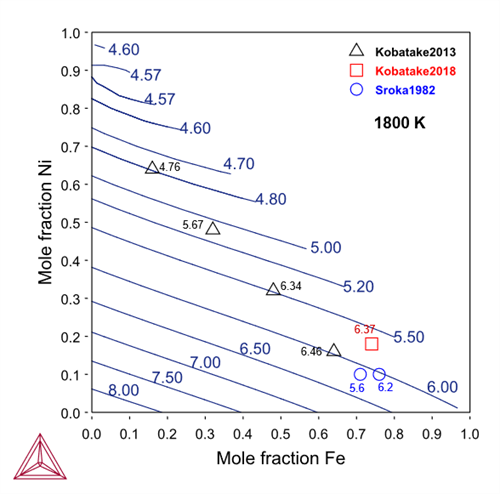

The isoviscosity Cr-Fe-Ni at 1800 K as calculated and plotted for the TCNI10 database using the new viscosity of liquid thermophysical property. There are many other examples using the other databases and these are included in the new Examples Collection PDFs and as part of the Help in Thermo-Calc.

Yield Strength Property Model Improvements

The Yield Strength Model in the Property Model Calculator has important accuracy improvements and has additional functionality when used in combination with the Precipitation Calculator and the Precipitation Module (TC-PRISMA).

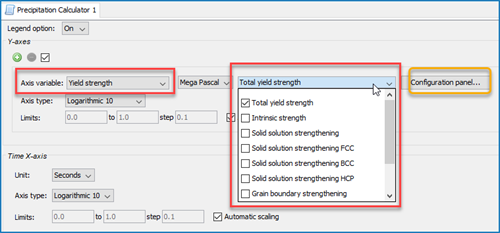

The Configuration window for the Plot Renderer 2 node as a successor to a Precipitation Calculator. This is from the updated P_01_Precipitation_Al-Sc_AL3SC.tcu example in Thermo-Calc. This example is available to all users.

The Precipitation Calculator Plot Renderer when “Yield strength” is selected as a plot variable. Click the Configuration panel button on the Plot Renderer to open the available settings for the Yield Strength Model. The greyed out sections (the Matrix and Precipitate phases) are defined on the Precipitation Calculator.

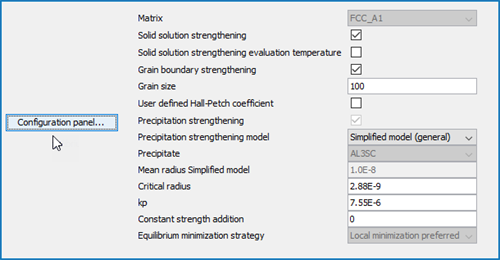

The new Process Schedule available with the Process Metallurgy Calculator will help you design realistic process schedules. This example, which is available as example PMET_06_Ladle_Furnace_Kinetics.tcu, shows how to model an 165 t industrial ladle furnace.

You can read about the EERZ model and its implementation into Thermo-Calc in two papers:

Two new application examples demonstrate the new model:

The new examples included with the 2020b release demonstrate how to set up kinetic simulations. The examples below are accessible from the Thermo-Calc menu Help > Example Files > Process Metallurgy Module

Highlights of the 2020b changes are

New Elements and Systems

New Metastable Phase

Updated Systems and Phases

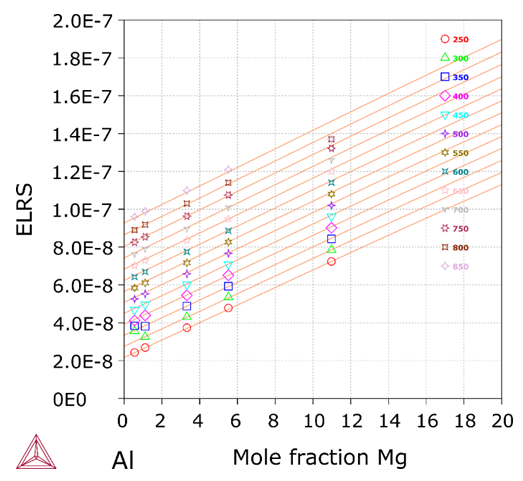

Using the TCAL7 database, this is the calculated electrical resistivity of the Al-Mg FCC_A1 solid solution in a wide temperature range from 250 K to 850 K, in comparison with data recommended by Ho et al. [1983], which were from “annealed” alloys. This plot is included in the new Examples Collection PDF and in the Help.

Reference: C. Y. Ho, M. W. Ackerman, K. Y. Wu, T. N. Havill, R. H. Bogaard, R. A. Matula, S. G. Oh, H. M. James, Electrical Resistivity of Ten Selected Binary Alloy Systems. J. Phys. Chem. Ref. Data. 12, 183–322 (1983).

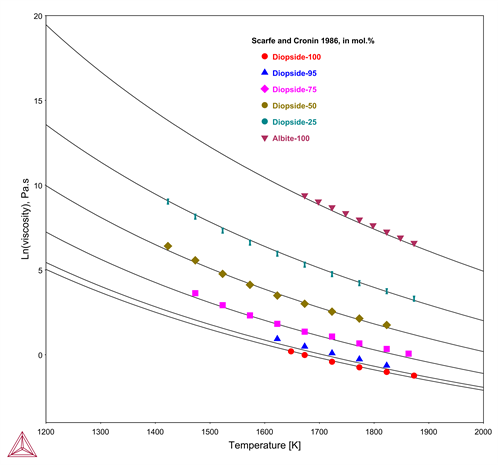

An example of viscosity of liquid in a calculation of a diopside-albite (MgCaSi2O6-NaAlSi3O8) system. With this new thermophysical property being available with TCOX10, it is possible to predict viscosity of the oxide slags for various industrial and mineralogical applications. Here, the solid lines represent the calculated viscosities of the diopside-albite system are compared with the experimental data by Scarfe et al. [1986]. This and many more examples are available in the new Examples Collection PDF.

Reference: C. M. Scarfe, D. J. Cronin, “Viscosity-temperature relationships of melts at I atm in the system diopside-albite,” Am. Mineral. 71, 767–771 (1986).

Highlights of the some other 2020b changes to this database are:

Highlights of the 2020b changes are:

Binary and Unary System Updates

Ternary System Updates

Phase Renaming

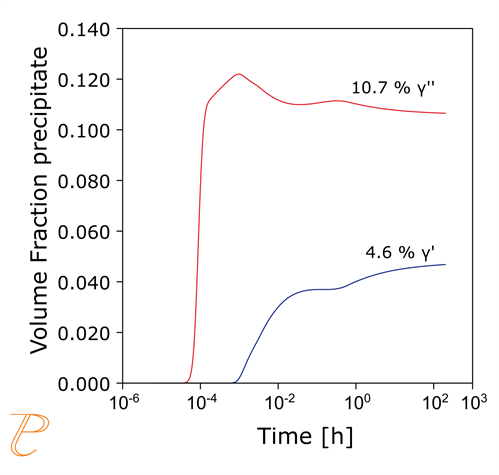

A new calculation example, available with the TCNI10 database documentation, uses the Precipitation Module (TC-PRISMA). Here the volume fraction of precipitates is simulated for 718-type alloy at 1023 K for 200 hours for a composition based on Sundaraman et. al. For more details, see the TCNI Examples Collection PDF.

Reference: M. Sundararaman, P. Mukhopadhyay, S. Banerjee, “Some aspects of the precipitation of metastable intermetallic phases in INCONEL 718,” Metall. Trans. A. 23, 2015–2028 (1992).

Six Updated Thermodynamic Databases

The following databases all had minor updates made for 2020b. Details of these changes are included in the Release Notes.

Users who have a license for an updated database and a valid Maintenance and Support Subscription receive the updated database for free.