Introducing Thermo-Calc 2019b and the New Process Metallurgy Module

New Features for the Diffusion Module (DICTRA)

The Diffusion module (DICTRA) has received several improvements in Thermo-Calc 2019b, some of which are included below:

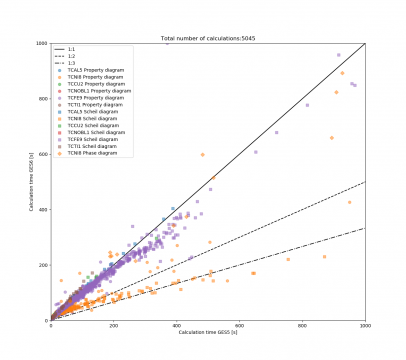

This plot compares the execution times between GES5 and GES6 from over 5 000 calculations on various industrial alloys. Points that are above the 1:1 ratio line (top line) show cases where GES6 is slower than GES5 and points below the 1:1 ratio line show cases where GES6 is faster than GES5. Points on the 1:2 ratio line (middle line) show cases where GES6 is twice as fast as GES5, and points on the 1:3 ratio line (bottom line) show cases where GES6 is three times faster than GES5.

Installation Updates

The installation of Thermo-Calc has changed in order to make the process more user friendly.

New Copper Databases for Thermodynamics (TCCU3) and Kinetics (MOBCU3)

Two new copper databases are released, the thermodynamic copper database, TCCU3, and the companion mobility database, MOBCU3.

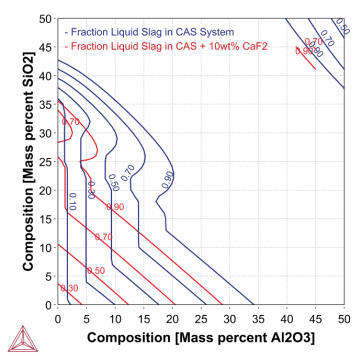

New Oxides and Slag Database (TCOX9)

A new oxide database, TCOX9, adds titanium, bringing it to a 25 element framework. The thermodynamic database for metal oxide solutions (including slags) also adds 19 binary systems, 26 ternary systems and 30 quaternary systems. The database includes several other updates:

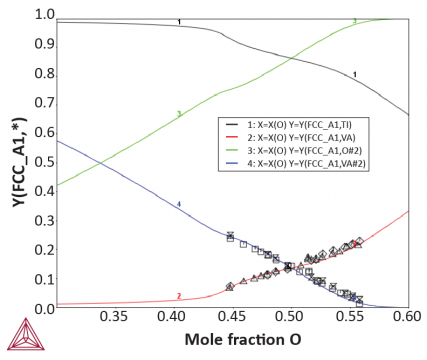

A plot showing the distribution of species at 1773 Kelvin in the TiO high temperature phase (FCC_A1).