Welcome to the Getting Started Guide for the Diffusion Module (DICTRA)

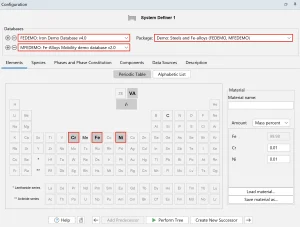

For this example:

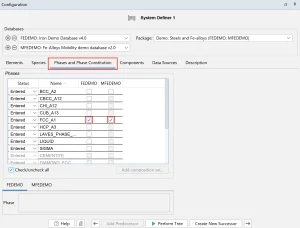

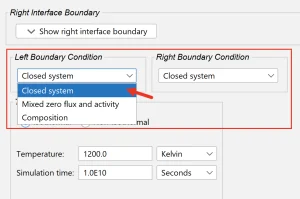

In this example, we will calculate at a temperature of 1200 K, and the material will be fully austenitic (only FCC phase) at that temperature. Therefore:

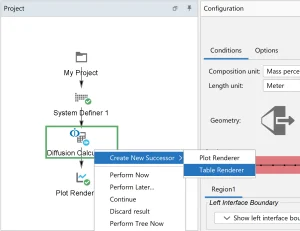

Select Units

In the Diffusion Calculator, you can set which length and composition units you want to use for your calculation. The default units are mass percent (wt%) and meter (m).

For this example:

Select Geometry

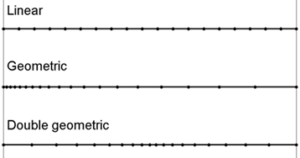

The Diffusion Module handles diffusion problems where composition varies along one spatial coordinate. You can choose planar, cylindrical, or spherical geometry.

For this example:

More About the Geometries

Planar

Cylindrical

Spherical

For this example:

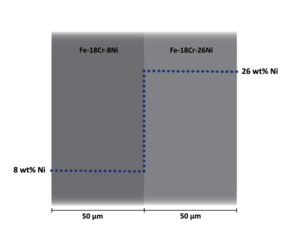

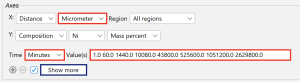

In this example, we will simulate how the Ni content varies between the two metal sheets with different Ni concentrations.

This will create a composition profile that simulates two materials with different nickel compositions, i.e. one with 8 wt% nickel and one with 26 wt% nickel. The composition profile is shown in the Visualizations window.

Note that the step in the center is not a phase interface, our setup represents a single phase FCC structure with a concentration jump.

For this calculation:

For this example:

For this example: