Applications to Failure Analysis

Thermo-Calc can be used as part of a failure analysis investigation by making calculations that:

Application Examples

Supplementing SEM/EDS with Thermo-Calc to Understand Failure Mechanisms

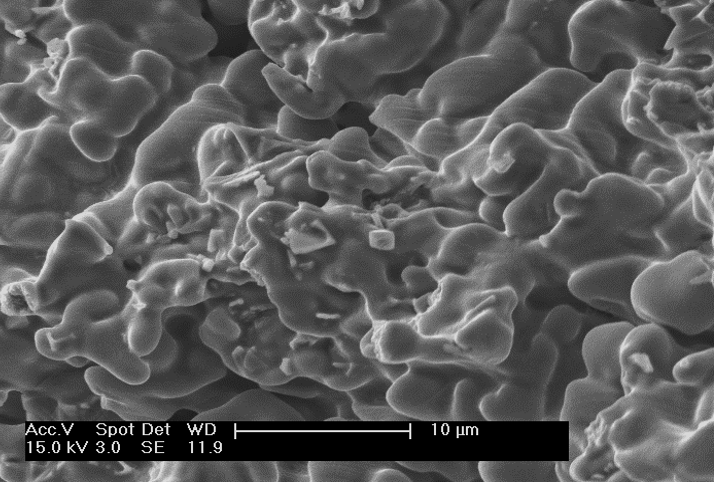

Root cause failure analysis often requires quantifying phases or precipitates on fracture surfaces. However, advanced sample extraction and characterization techniques, for instance Focused Ion Beam (FIB) and Transmission Electron Microscopy (TEM), can be difficult to access. More common techniques like Scanning Electron Microscopy (SEM)/ Energy Dispersive Spectroscopy (EDS) can only give qualitative results when the surface is not flat or the particles are less than 1 µm in diameter. Coupling qualitative EDS information with a Thermo-Calc calculation gives a clearer picture of the failure mechanism.

This SEM backscatter image shows a solidification crack in a Ni-based alloy weld metal. The particles are enriched in Titanium, based on EDS scans. Thermo-Calc predicts that a eutectic γ+Ti(C,N) forms at the end of solidification, likely leading to cracking in this alloy.

Learn more about Applications to Failure Analysis

Failure and fracture analysis of a high-alloy Ni-Al bronze chain connector of a tube drawing machine