Thermo-Calc 2025b Available Now

Databases and Thermophysical Properties

New Databases

TCMG8: Mg-based Alloys Database

The database has been enhanced to perform rare earth (RE) calculations for Mg-RE-Sn systems (RE=Ce, La, Nd, Pr).

Updated Databases

MOBSLD2.1: Solder Alloy Solutions Mobility Database

MOBSLD2.1 is available for free to everyone who has MOBSLD2 and a current Maintenance & Support Subscription.

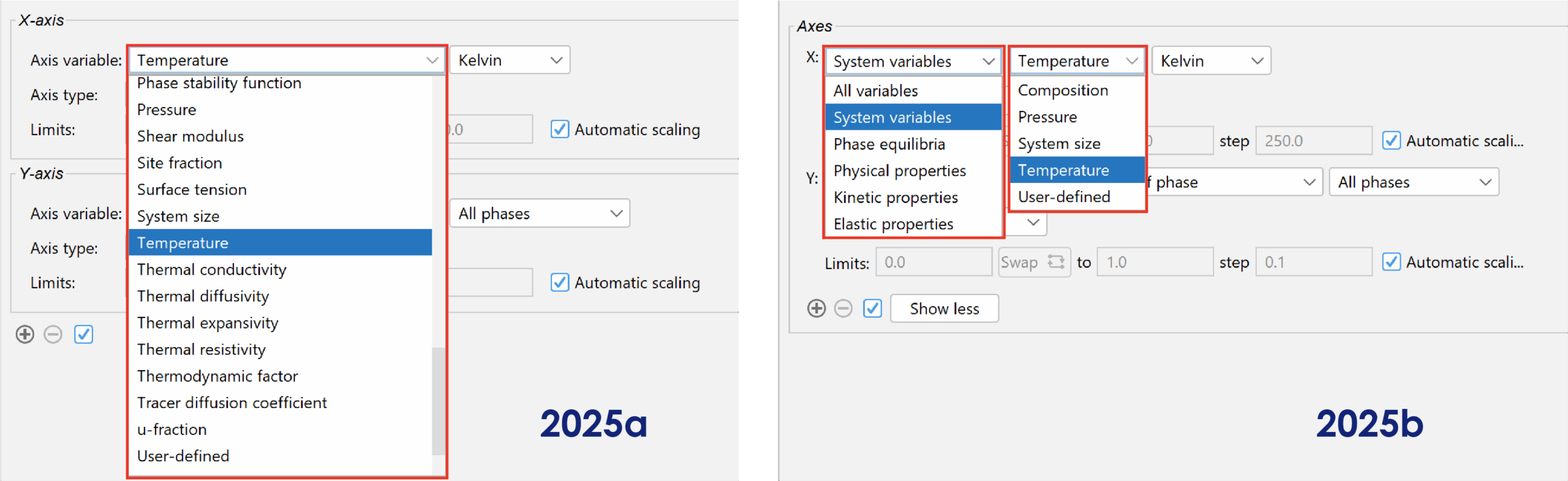

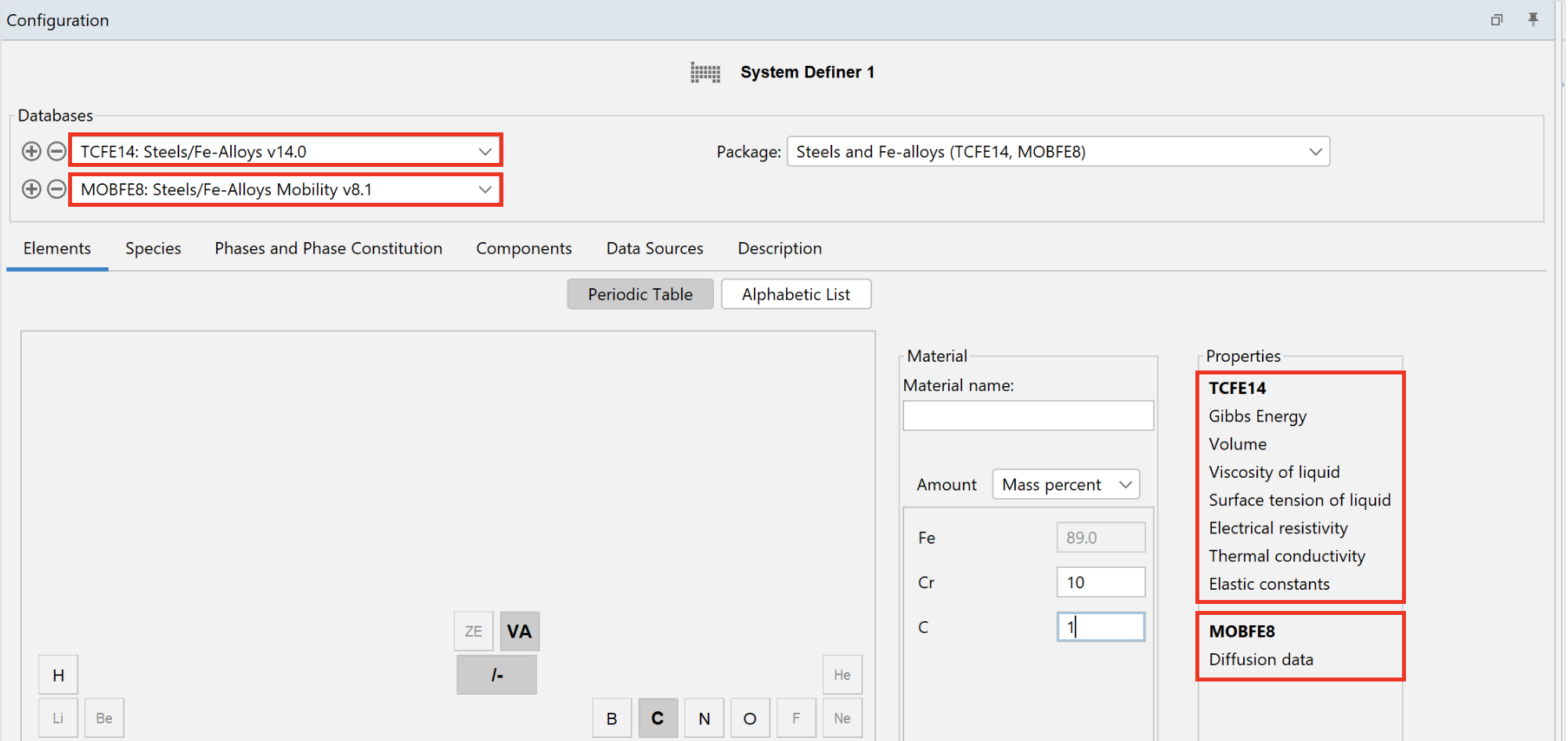

Database Properties Displayed in System Definer

As we’ve continued adding properties to our databases, it’s become increasingly difficult to keep track of which databases include which properties. With this release, that changes: now, when you select a database in the System Definer, its available properties are listed in the same window, making it easier than ever to find the information you need.

Note that the software simulates many more properties than those listed. The list only includes database-specific properties, which are:

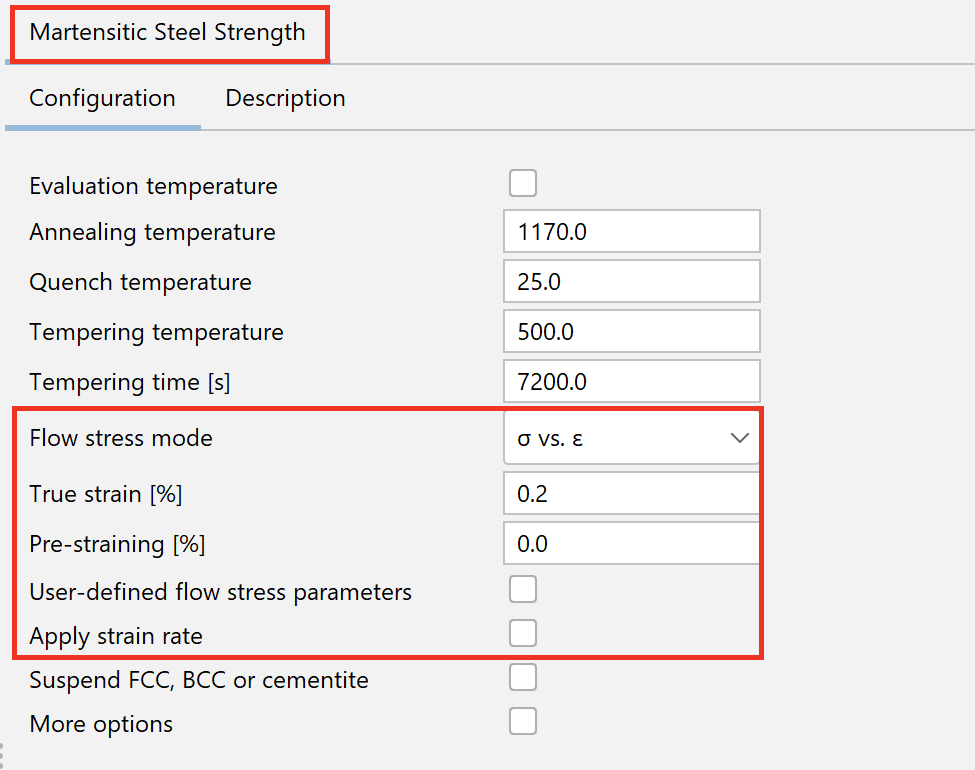

Steel Model Library adds Flow Stress Model for Martensitic Steels

The Martensitic Steel Strength Model has been extended to a full flow stress model in this release, able to predict stress at arbitrary strain in the form of the following properties:

The model is also equipped with a mode to predict engineering properties such as:

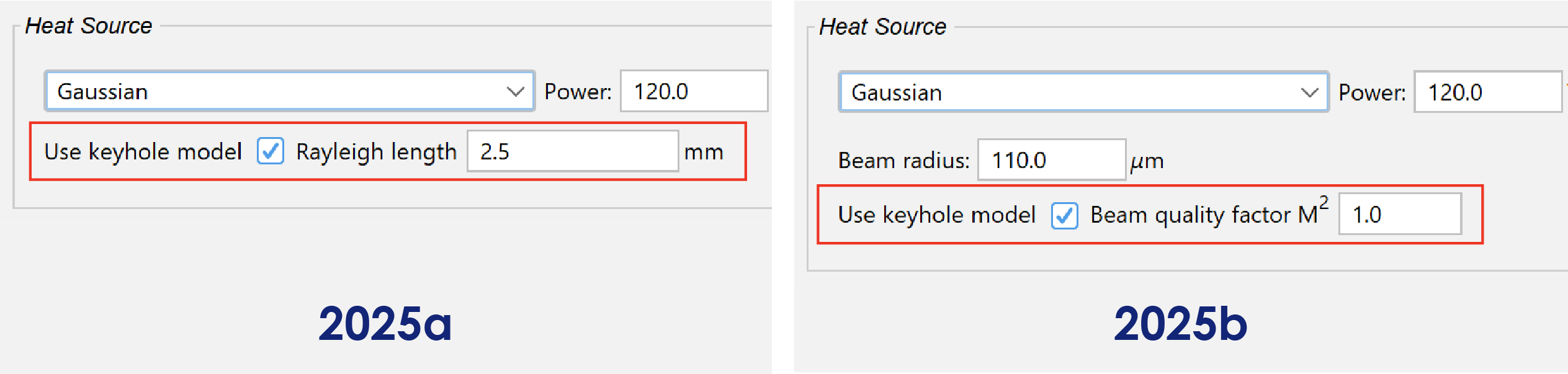

Flow stress curves calculated at 2, 5, and 50 hours for a 15-5PH steel alloy (left) using the new settings in the Martensitic Steel Strength Model, including Flow stress mode, True strain, and Pre-straining (right).

Note: True strain is not available as an input parameter when using the engineering properties mode.

Additional updates and changes have been made to the model to accommodate this valuable extension, which you can read about in the Release Notes.

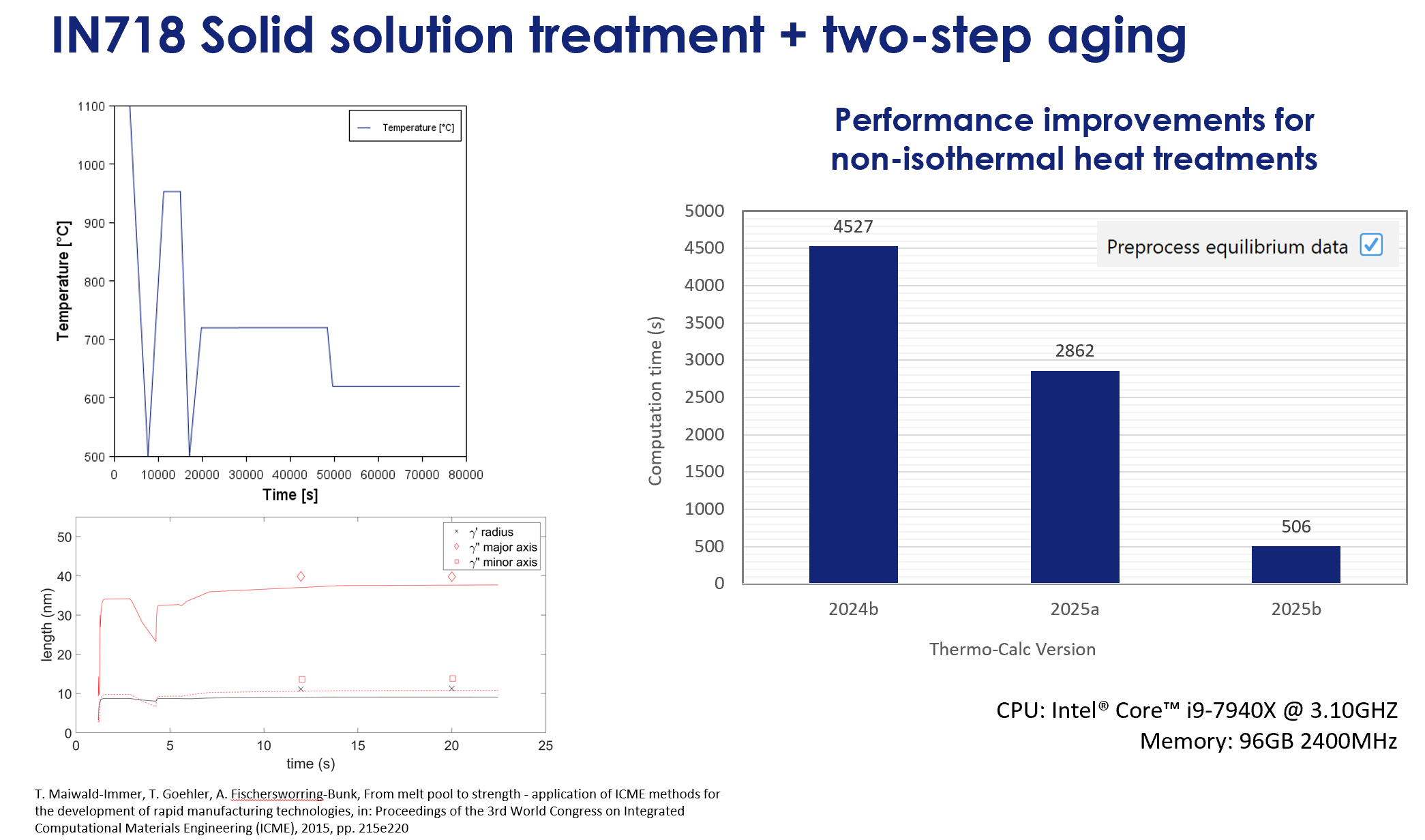

Precipitation Module (TC-PRISMA) Receives Significant Speed Improvements and Improved Meshing

Speed Improvements

The Precipitation Module (TC-PRISMA) receives a significant improvement in computation speed for non-isothermal simulations. For example, the computation time to simulate a solid solution treatment with a two-step aging of IN718 has been reduced by more than 80% compared to 2025a, as shown in the image.

Improvements have been made to the computation time for non-isothermal simulations. For example, simulating the solid solution treatment and two-stage aging of gamma prime, gamma double prime, and delta in IN718 has reduced from 4500s in 2024b to 500s in 2025b.

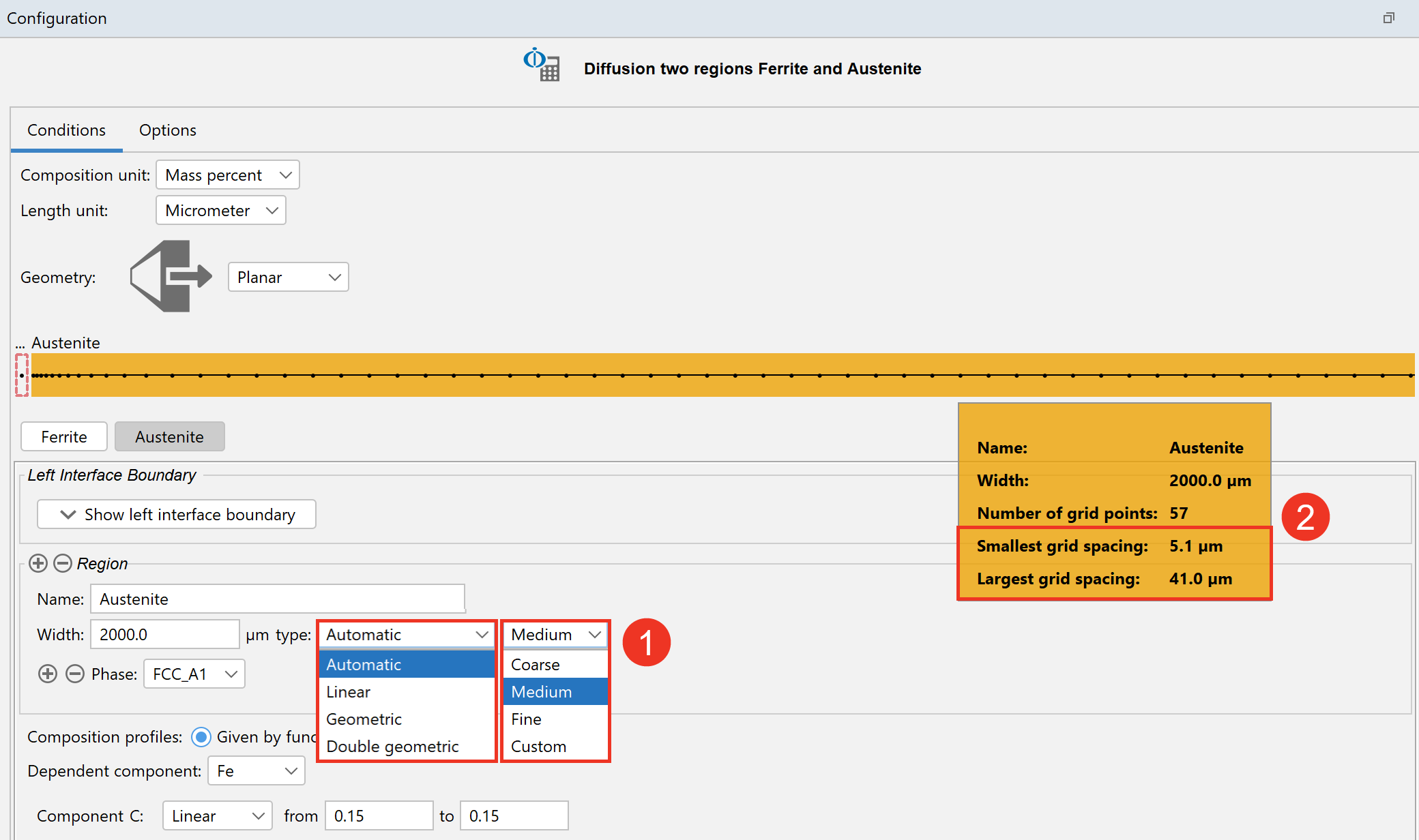

Improved Meshing

An improvement has been made to the meshing of precipitate size distributions when using PE and PE-automatic growth rate options to make results more accurate. This improvement can be seen in examples P_13 and P_15, which are included in the software.

![Two plots showing a comparison between the measurements of mean cementite radius from [2007Miy] with the simplified (OE), para-eq (PE), and PE Automatic (PE-OE) growth models. Left is from Thermo-Calc 2025a and right is from 2025b, after accuracy improvements were made to the meshing of precipitate size distribution.](https://thermocalc.com/wp-content/uploads/Images/Plots/p-15-2025a-vs-2025b.svg)

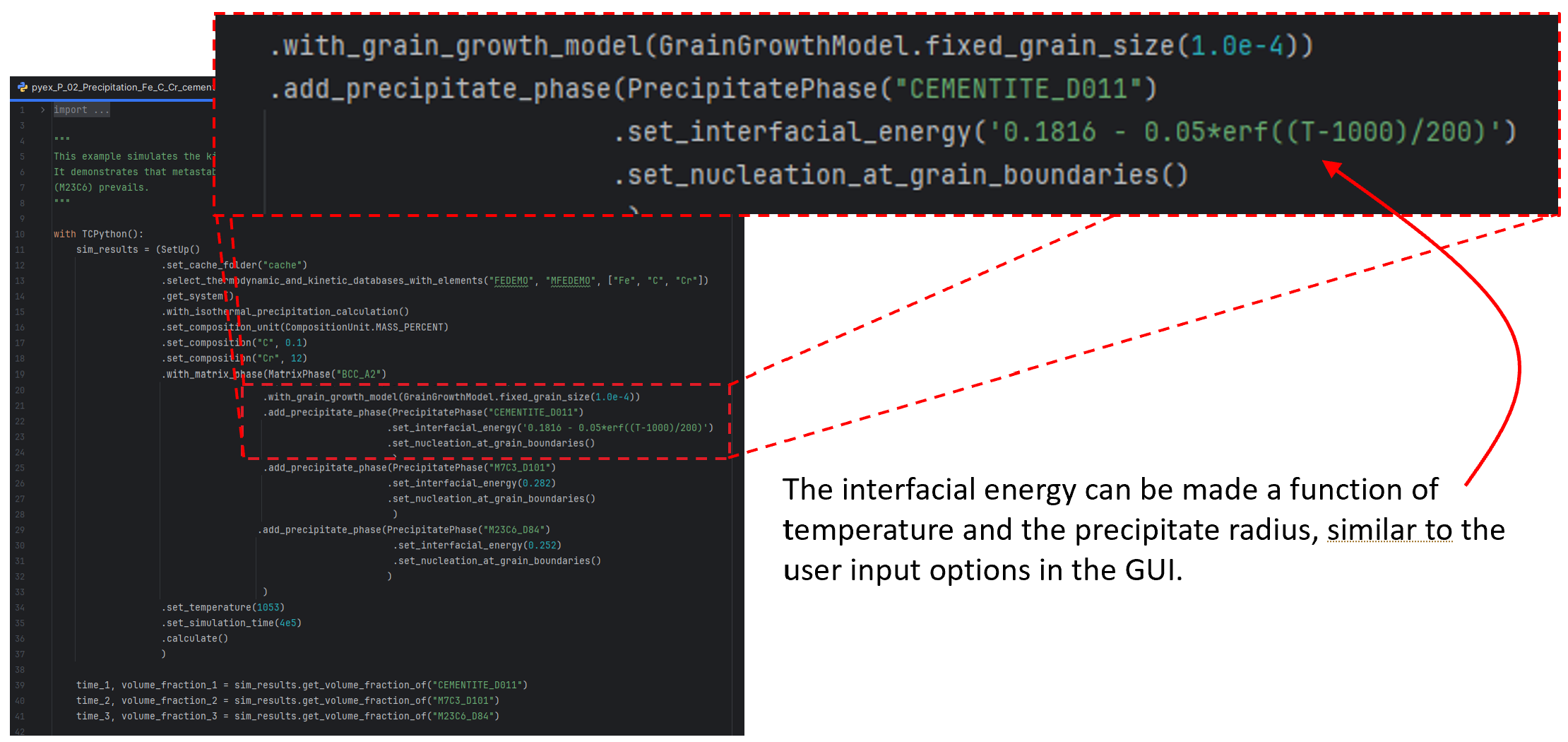

User Defined Expressions for Interfacial Energies of Precipitate Phases added to TC-Python

It is now possible to create user defined expressions for interfacial energies of precipitate phases in TC-Python for use in the Precipitation Module.

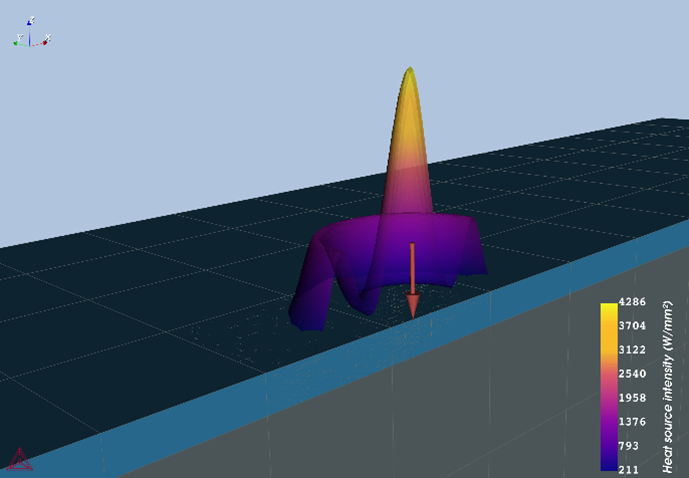

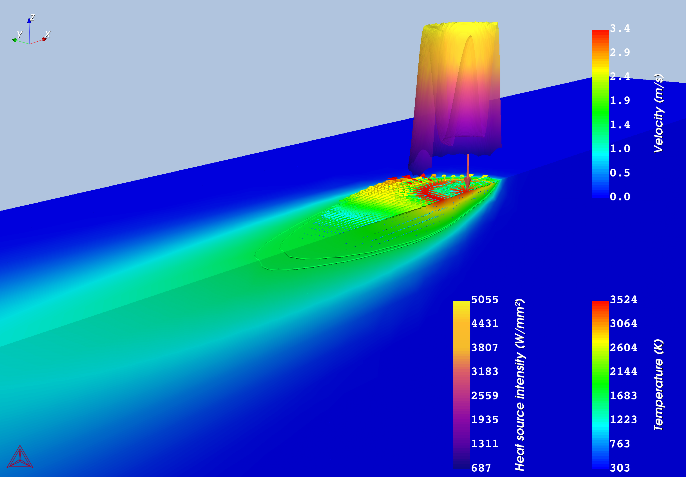

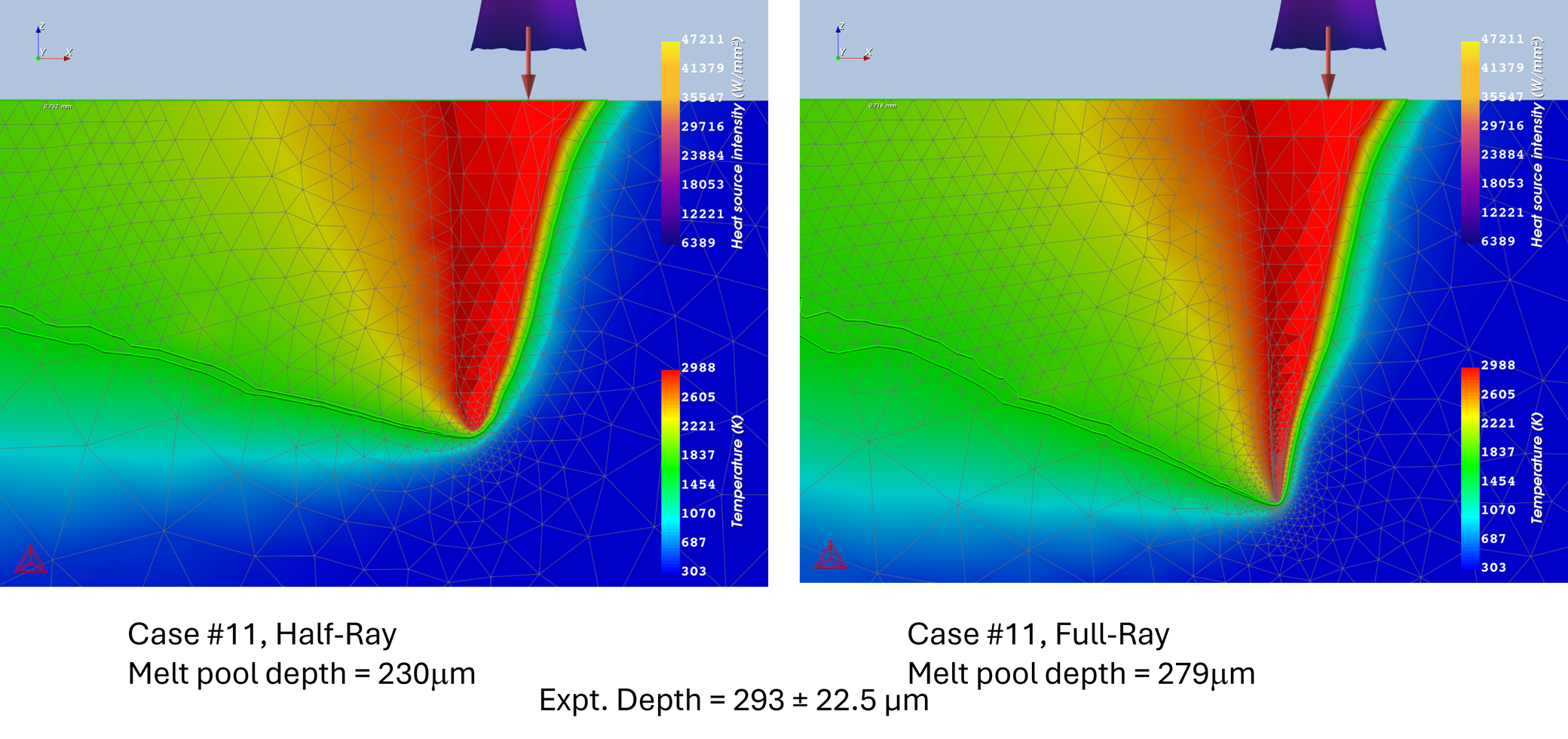

Two new examples are available demonstrating the new beam shapes: