OUR ICME AND MATERIALS DESIGN

Services

Reduce development time with our modelling and design services

On-time and efficient delivery of services tailored to your development needs

Avoid experimental trial-and-error; get it right from the beginning

Reliable and high-quality modelling results and recommendations

Minimize risks and costs related to design, development and upscaling

Physics-based models and advanced statistics replaces pure empirical confidence

POWERFUL SOFTWARE COMBINED WITH VALIDATED METHODOLOGY

Solving Materials-based Challenges

Our team of experts ensure fast, reliable, high-quality delivery of services, from specific calculations and analysis to complete ICME evaluation, and materials & process design.

Working closely with your engineers, we identify, plan, and execute on the modelling and design activities that provide the most value to your development project.

All services are tailored to your specific needs.

Solutions Across Industries

Reliable performance

Space, Aerospace and Defense

Enabling next-gen capacity by enhanced performance and reliability of flight-critical and mission-limiting components.

Lightweight

Automotive and Transport

Minimize costs and weight by optimized materials and processing solutions.

Efficiency

Energy & Raw materials

Increase efficiency while reduce costs and environmental impact using superior materials for demanding applications.

Robustness

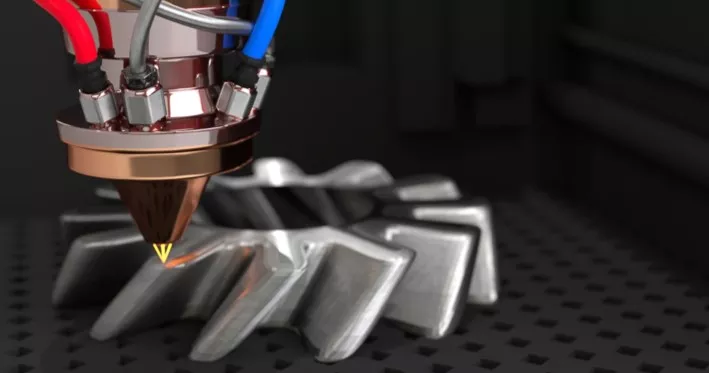

Process industry & Manufacturing

Enhanced yield, reliability, and sustainability of industrial processes. Accelerated uptake and upscaling of advanced manufacturing technologies.

Example Services Provided to Industry

ICME Evaluation of Your Material

Analysis and select modelling of process-structure-property-performance links for your current material and process. Evaluation of sensitivity to process variables.

Deliverable: Identification of materials & process optimization strategies

Material Selection for a New Product

Analysis and modelling of select properties / processability metrics. Screening a range of materials based on performance needs and processing constraints.

Deliverable: Recommended materials for experimental testing and up-scaling

Optimized Heat Treatment Cycle

Analysis of problem and client data, and modelling heat treatment effects on properties, including uncertainty quantification. Optimization for robust and reliable properties.

Deliverable: New heat treatment schedule to enhance product quality & yield

Refined Composition Specification

Analysis and modelling effects of microstructure and properties. Uncertainty quantification and optimization of alloying content and allowable impurity ranges.

Deliverable: New composition specification for your supply chain

Proven Collaboration

New Tanbium Alloy Evaluated for 3D Printing Rocket Components

Thermo-Calc Solutions is working with Metalysis and Skyrora to test and evaluate a novel alloy we developed, Tanbium, for suitability in space applications.