About the Steel Model Library

The Steel Model Library is a package of property models used to set up calculations in the Property Model Calculator. The library currently includes nine models intended for those working in the steel industry: Martensite Temperatures, Martensite Fractions, Martensitic Steel Strength, Critical Transformation Temperatures, Pearlite, Bainite, Ferrite, CCT, and TTT Models.

The Steel Model Library is available for free to all users who have a license for the steel and Fe-alloys thermodynamic database TCFE version 9 or newer and the mobility database MOBFE version 4 or newer, and a current Maintenance & Support Subscription (M&SS).

Martensite Temperatures Model

The Martensite Temperatures Property Model calculates the martensite start temperature (Ms) based on modeling the transformation barrier. The Model is based on Stormvinter et al. (2012) with subsequent update and extension by Gulapura Hanumantharaju (2018) and Thermo-Calc internal assessment. The partitionless equilibrium temperature T0 is calculated using the thermodynamic database. The model also gives temperatures corresponding to 50%, 90%, and 99% transformations. Martensite fractions are calculated with the same algorithm as in the Martensite Fractions Property Model.

The plot shows all the Ms temperatures of different types of martensite morphologies (lath, plate, and epsilon (hcp)) compared with experimental epsilon Ms values.

Martensite Fractions Model

The Martensite Fractions Property Model calculates the fraction of athermal martensite based on a model developed in Huyan et al. (2016). It is assumed that the first forming martensite morphology is the only forming one. The first morphology is determined based on the Ms-temperatures of all morphologies.

The image is a plot of the transformation curves showing Fe-Cr-C martensite with intercritical annealing.

Martensitic Steel Strength Model

The Martensitic Steel Strength Property Model calculates the strength and/or hardness of martensitic steels. It is based on the Intrinsic Strength and Solid Solution Strength models available in the General Yield Strength model with the addition of a strengthening contribution from the formation of martensite. The Martensite Fractions model is used to evaluate the fraction transformed austenite upon quenching. Furthermore, the effect of tempering as a function of tempering temperature and time is also modeled. From 2025b release, strain hardening response (flow stress) based on the final hardness after tempering can be simulated for martensitic steels.

The first plot shows the calculated hardness after tempering versus tempering temperature and time compared to data from Grange, R.A. and Baughman, R.W. (1956) Hardness of tempered martensite in carbon and low alloy steels, Transactions of American Society for Metals, Vol. XLVIII, pp.165–197.

Martensitic Steel Strength Model - Flow Stress

The Martensitic Steel Strength Model is also able to predict the general flow stress properties of martensitic steels. The model predicts stress at arbitrary strain in the form of the following properties: true stress, true strain (user input), engineering strain, and engineering stress.

The model is also equipped with a mode to predict engineering properties such as yield strength, yield strain, ultimate tensile strength, uniform elongation, fracture strength, elongation at fracture, and Young’s modulus.

The second plot for the Martensitic Steel Strength Model shows the true stress (MPa) -true strain (%) curves for a 15-5 PH steel aged for 2h, 5h, and 50h at 500 ⁰C compared to data from Croné, P., Zhou, T., Hedström, P., Odqvist, J., Gudmundson, P., & Faleskog, J. (2022). Continuum plasticity modelling of work hardening for precipitation-hardened martensitic steel guided by atom probe tomography, Materials & Design, Vol. 215, Article 110463.

Critical Transformation Temperatures Model

The Critical Transformation Temperatures Property Model calculates critical transformation temperatures for steels. This Property Model can output the transformation temperatures for the following:

- Liquidus: First austenite or ferrite transformation from the liquid

- Solidus: Liquid fully transformed to solid

- A0: Magnetic transformation (Curie temperature) of cementite. The cementite is paramagnetic above A0 and ferromagnetic below

- A1: Austenite (FCC_A1) transforms to ferrite (BCC_A2) + carbide (cementite or graphite or M23C6)

- A2: Magnetic transformation (Curie temperature) of ferrite (BCC_A2)

- A3: Austenite (FCC_A1) transforms to ferrite (BCC_A2)

- A4: Delta-ferrite (BCC_A2) transforms to austenite (FCC_A1)

- Acem: Austenite (FCC_A1) transforms to cementite

- Agraph: Austenite (FCC_A1) transforms to graphite

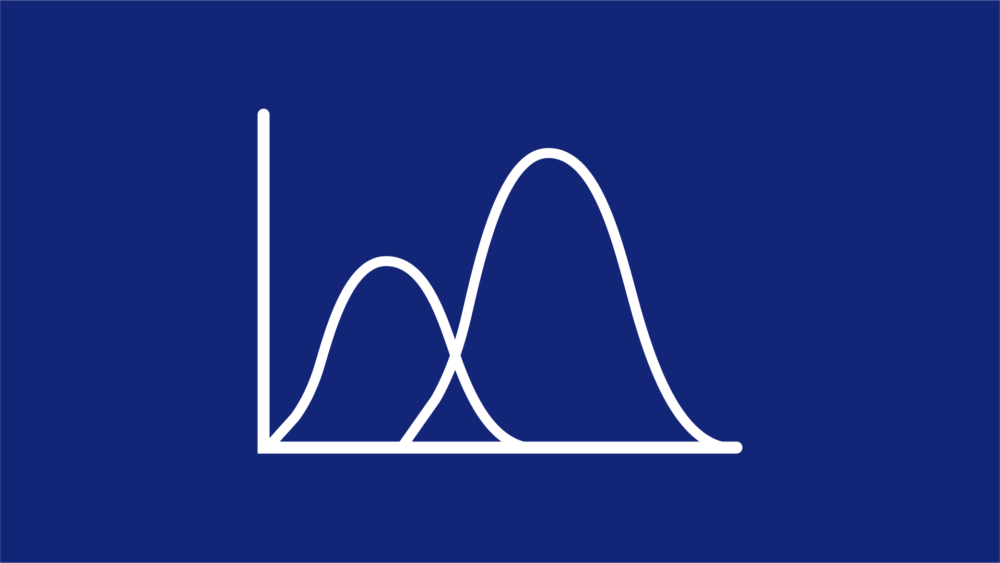

The plot shows the distribution of the A1 and A3 phase transition temperatures for a low alloyed steel (Fe-0.3Cr-1.0Mn-0.3Mn-0.18C) when the composition is varied within the specification.

Pearlite Model

The Pearlite Property Model describes the thermodynamics and kinetics of pearlite formation from austenite during isothermal heat treatment. It is assumed that the overall composition of pearlite is the same as the austenite composition, and growth rate is constant over time. Growth rate and lamellar spacing of pearlite are determined by a criterion where either growth rate or Gibbs energy dissipation rate is maximized. The model considers Gibbs energy dissipation due to formation of ferrite-cementite interface in pearlite, finite austenite-pearlite interfacial mobility, solute drag, and diffusion of elements within austenite and along austenite-pearlite interface. A complete description of the model is available from Yan et al. (2020).

The plot is a TTT (time-temperature-transformation) diagram showing times of start (2% transformation) and finish (98% transformation) as functions of isothermal heat treating temperature in an Fe-0.69C-1.80Mn alloy (mass %).

Bainite Model

The Bainite Model describes the thermodynamics and isothermal kinetics of bainite transformation from austenite. This Model can calculate bainite start temperature, transformation times, bainite plate lengthening rate, and phase constitution at the final state. In this Model, bainite is modeled as either ferrite or a ferrite-cementite mixture, depending on the driving force of cementite precipitating at the ferrite/austenite interface.

WBs is calculated following Leach et al. (2018) by a driving-force-barrier balance approach. Lengthening rate is calculated by extending the approach from Leach et al. (2019) to account for interfacial mobility and possible cementite formation in bainite. The overall kinetics of bainite transformation is calculated in the extended-volume approach, with considerations for both grain-boundary nucleation and volume nucleation of bainitic plates.

The plot is a TTT diagram which shows the calculated start (2%), half (50%), and finish (98%) curves of bainite as compared to the experimentally measured 1% transformation times. The alloy is a hypereutectoid steel with the composition Fe-0.97C-0.72Mn-0.32Si-1.54Ni-0.8Cr-0.26Mo (mass %).

Ferrite Model

The Ferrite Model describes the thermodynamics and isothermal kinetics of ferrite transformation from austenite. This Model is specific to the so-called grain-boundary allotriomorph, or polygonal ferrite. (Widmanstätten ferrite is treated in the Bainite Model.) This Model can calculate diffusional growth rate constant, grain-boundary nucleation rate, and isothermal transformation times of ferrite.

The overall kinetics is calculated in the extended-volume approach, with considerations for grain-boundary nucleation and a mixed-control growth of ferrite particles. Nucleation rate of ferrite allotriomorph on austenite grain boundaries is calculated from classical nucleation theory assuming a pillbox shape of the ferrite nucleus, following Lange et al. (1988). Growth is calculated using a mixed-control model considering diffusion in austenite and a finite interfacial mobility, and any solute-drag effects. Composition of the growing ferrite is determined from prescribed conditions, which is simpler and faster than solving diffusion and local-equilibrium equations rigorously (like in DICTRA).

The plot shows the calculated ferrite start (2%) of an Fe-0.11C-3.28Ni (mass %) alloy, in orthoequilibrium (OE) and paraequilibrium (PE) modes, as compared to the experimental ferrite start data.

Easily Set Up CCT & TTT Diagrams

CCT Diagrams

The CCT mode in the CCT template makes it easy to set up CCT diagrams by allowing users to define the axes for the plot and automatically arrange the calculation results, which are time-temperature pairs.

The plot is a CCT diagram for an En 18 1% chromium steel (Fe-0.48C-0.86Mn-0.25Si-0.18Ni-0.98Cr-0.04Mo, mass %) with a grain size of 53 micrometers, made using the CCT template and the CCT plotting mode. The CCT diagram shows the starts of ferrite, pearlite, bainite, martensite, together with 50%- and 98%-transformations of austenite, under different cooling rates. Selected cooling curves are also added automatically in the CCT mode.

TTT Diagrams

The TTT template includes a plotting mode called TTT mode, which is used to define Temperature on the y-axis and Time on the x-axis for all selected quantities. For example, as shown in the TTT diagram here, transformation times for 2% ferrite/pearlite/bainite and 50% and 98% austenite transformation are shown as functions of reaction temperature. Additionally, time independent results, like the Ms temperature, are drawn as horizontal lines.

The plot is a TTT diagram for an En 18 1% chromium steel (Fe-0.48C-0.86Mn-0.25Si-0.18Ni-0.98Cr-0.04Mo, mass %) with a grain size of 53 micrometers, made using the TTT template and the TTT plotting mode. The TTT diagram shows transformation times for ferrite start (2%), pearlite start (2%), bainite start (2%), austenite transformation 50% and 98%, and time independent results, like the Ms temperature, which are drawn as horizontal lines.

Steel Model Library Examples

Steel Models References

Learn More about the Steel Model Library

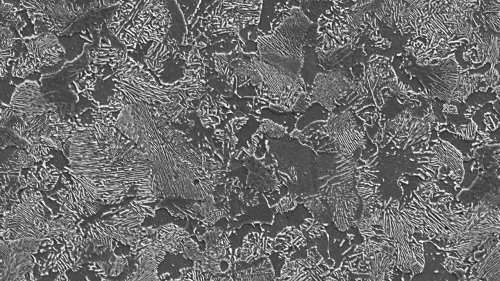

Microstructural and mechanical properties of a novel cobalt and titanium free maraging steel for laser powder bed fusion

Calphad-assisted design of high strength – ductility martensitic stainless-steels with reverted austenite