Webinar

CALPHAD- and ICME-based Approach

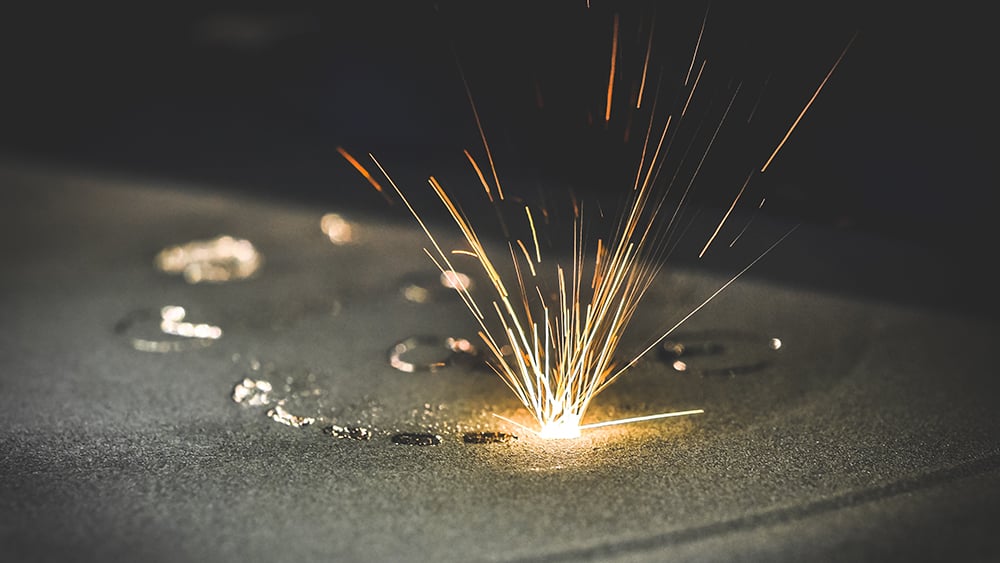

Accelerated Design of Printable Superalloys for Additive Manufacturing

The growing demand for high γ’ superalloys in energy and aerospace additive manufacturing applications cannot be met by legacy alloys such as alloy 247 LC or 738 that experience severe cracking during printing. This started a race to design novel alloys that are inherently resistant to solidification and strain-age cracking and have the required strength and stress rupture properties at high temperature.

GammaPrint™-1100, a novel powder superalloy with 55 to 60 vol. % γ’, was specifically designed to be amenable to laser powder bed fusion and electron beam melting fabrication without cracking. It has room temperature tension properties similar to those of alloy 939 but maintains yield strength and ultimate tensile strength 200 °C higher than 939 without debt in hot ductility. This presentation will review the early alloy design phase and product development with a special emphasis on the CALPHAD thermodynamic models used and the ICME approach.

GAMMAPRINT is a trademark of CRS Holdings, LLC, a subsidiary of Carpenter Technology Corporation.

Topics will Include:

- Alloy and property diagram calculation to identify a suitable composition space and equilibrium microstructure

- Solidification and process simulation to mitigate cracking

- Equilibrium and kinetic modeling during heat treatment to develop an ideal γ/γ’ microstructure

This webinar is part of our Expert User Series, which invites experts from industry and academia to present their work with Thermo-Calc products.