Application Example

Titanium Alloy Design for Additive Manufacturing

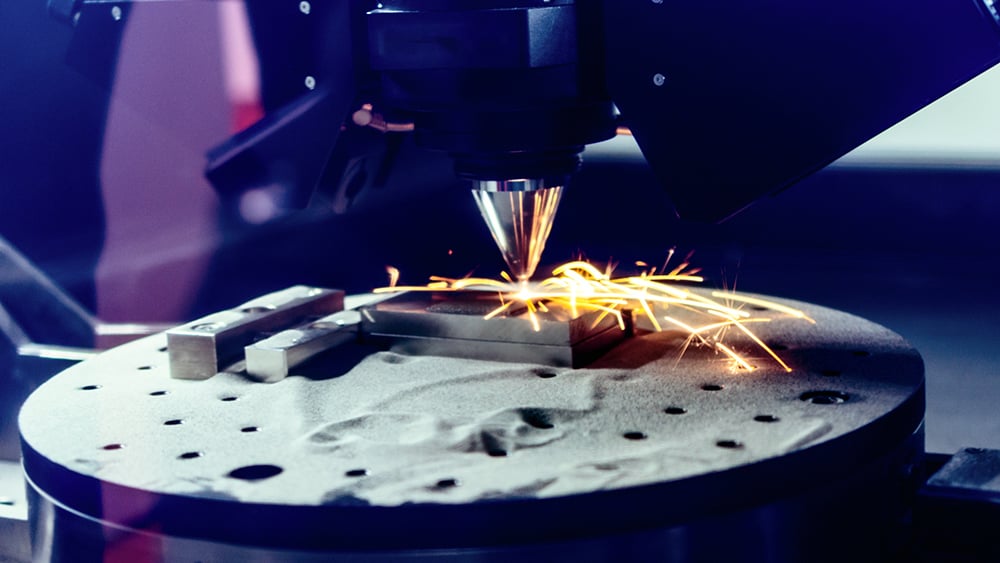

Additive manufacturing provides new opportunities to fabricate complex parts. However, traditional alloys may not be readily printable using techniques such as laser powder bed fusion. As such, the development of new alloys may be necessary to fully realize the benefits of additive manufacturing technologies.

In this example, inspired by the work of Ackers et al. [A. Ackers, O. M. D. M. Messé, U. Hecht, J. Alloys Compd. 866, 158965 (2021)], batch calculations within the Property Model Calculator are used to identify candidate titanium alloy chemistries for biomedical implant applications using the thermodynamic TCS Ti/TiAl-based Alloys Database (TCTI). To optimize printability and material weight, the liquidus temperature, solidus temperature, and density of 2000 randomized titanium alloy chemistries from the Ti-Nb-Zr-Sn-Ta-Fe-Mo system are calculated. An estimate of alloy cost is also made for each alloy. Taken together, this methodology can be used to identify compositions of interest and accelerate material development activities.

About this Application Example

This Application Example includes an in-depth PDF with a description of the materials problem, explanations of all the calculations made in Thermo-Calc to explore the problem, and interpretation of the results.

Users who have a license for Thermo-Calc 2022b or newer and the Titanium and TiAl-Alloys Database TCTI4 or newer can access the calculation files from within the software.